Making BRUSHSTROKE, 2021

I'm used to making site specific sculptures for spaces that don't yet exist...but this was the first (and hopefully only) time a global pandemic kept me from doing a site visit, overseeing fabrication in person, or supervising the installation. In fact, I have never seen BRUSHSTROKE in person (as of this writing)! None of this would have been possible without the incredible folks at UAP Shanghai.

All of my permanent site specific projects start with a scale model, and over the years, despite my shaky math skills, I’ve come to really enjoy building them. However, figuring out how to say "foam core" in Spanish and finding it during the Covid lockdown took weeks. Nothing was open and no one understood the materials I needed. I finally found everything I needed at Servei Estació in Barcelona, one of the coolest art/craft stores ever! I think we may have broken some laws by driving there during lockdown...

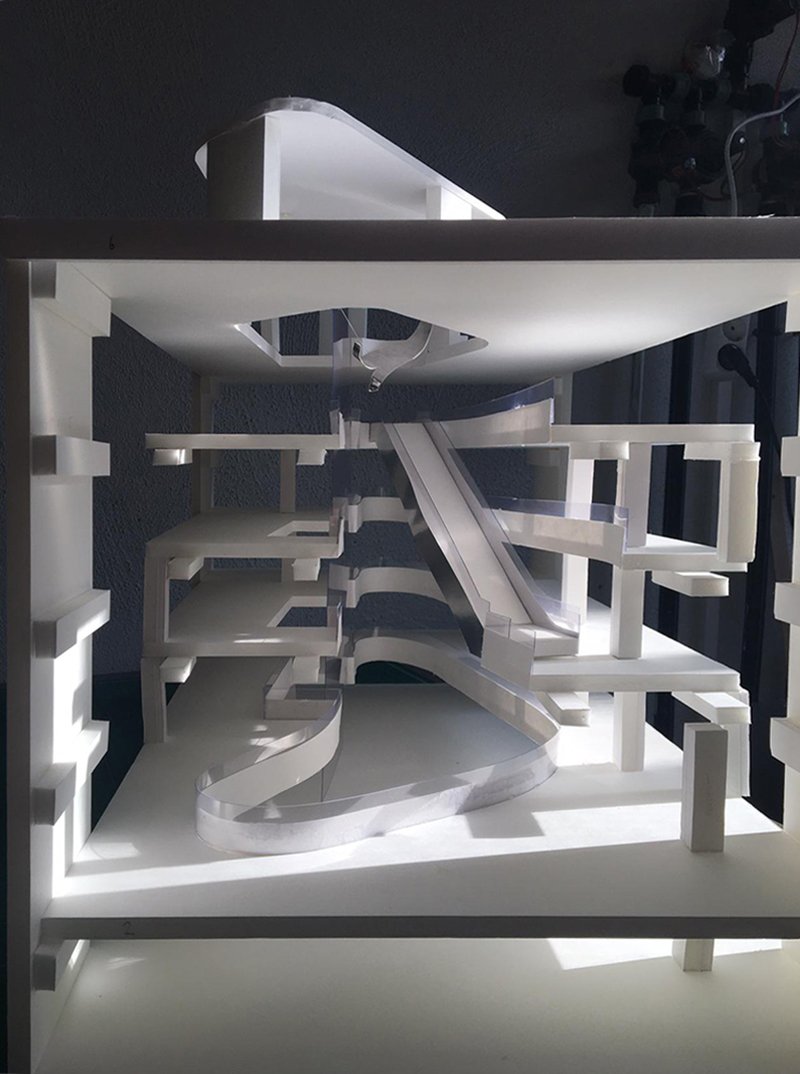

I built the model for BRUSHSTROKE in my brother-in-law’s unheated garage in a small village in Catalonia in January 2021, where my family escaped so our young kids could go to school during Covid and avoid the snow for a few months. As evidenced by my two pairs of socks + insulated slippers, two pairs of pants, three sweaters and warmest hat ever from the dollar store in my Brooklyn neighborhood! This model was super complicated to build because every floor in the Zhongshan Huafa Plaza is a different shape. I needed a model so I could understand the void in the center and where I could make a sculpture in it. The top level around the windows is actually a park 20+ meters above street level. I built a model where half the building could slide out so I could get my hands inside to play with the pieces. The hardest part honestly was finding model materials—I had to order metal roof flashing from the U.S. to make the sculpture pieces!

This was the state of construction when I came into the project. But I had a lot of renderings and architectural plans which I diligently converted from millimeters to inches and back to millimeters, because I was in my brother-in-law's garage with an American ruler and a metric cutting mat. Have I mentioned my shaky math skills?

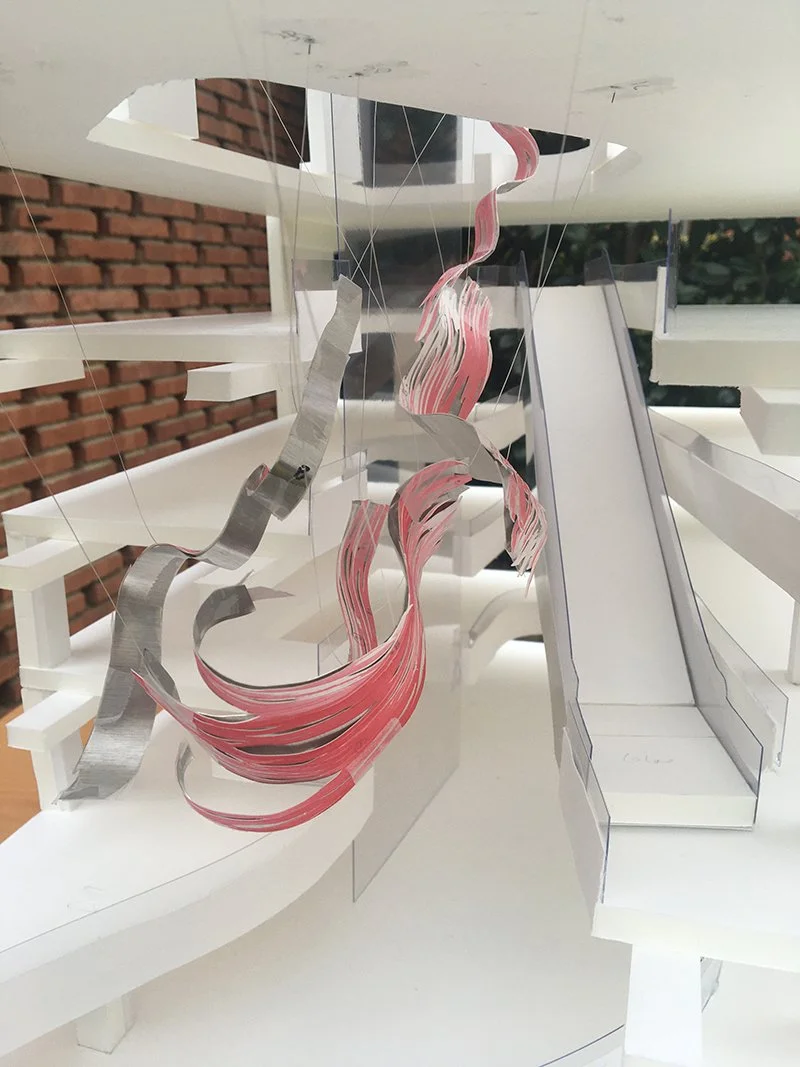

I didn’t have time to vectorize and cut metal pieces like I usually do, so I made paper cut outs and taped them to the metal forms (made of Home Depot roof flashing). I photographed these from every angle, from which UAP in Shanghai somehow made a digital 3D model. This allowed them to print the forms for an enormous physical scale model—like 2 meters long.

After we returned home, I made a slightly bigger scale model in my Brooklyn studio with some necessary tweaks to the sculpture, and the rest of the project was all digital.

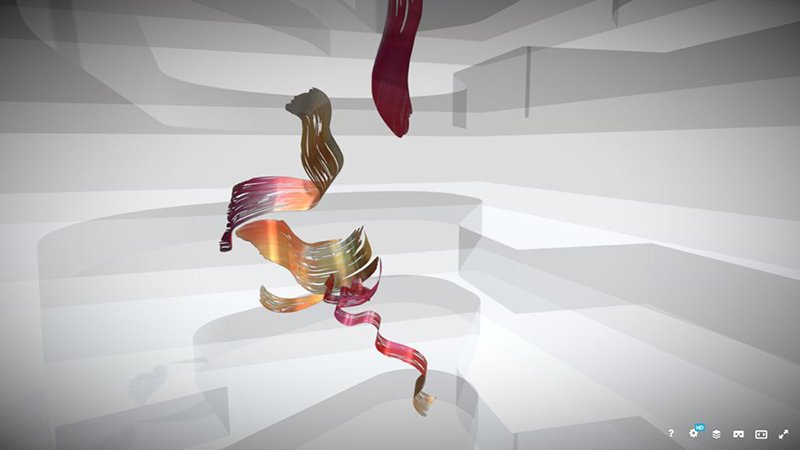

UAP created renderings for me to see how the sculpture would look as we made various to tweaks to the position of the pieces, heights, sizes and colors. These types of changes are necessary in every project.

They also made super cool, animated 3D models I could manipulate from my studio. Additional changes were made over Zoom calls using screen sharing at 10pm Brooklyn time/10am Shanghai time. I directed the changes ("Could you please move the bottom of piece #5 clockwise 30 degrees?") and UAP Shanghai changed the sculpture in Rhino while I watched.

We emailed Photoshop files back and forth to refine the colors. This was especially nerve-wracking, because so much of how color appears depends on lighting, which I couldn't control.

Zoom calls live from my bedroom during Covid lockdown when I couldn't get to my studio...

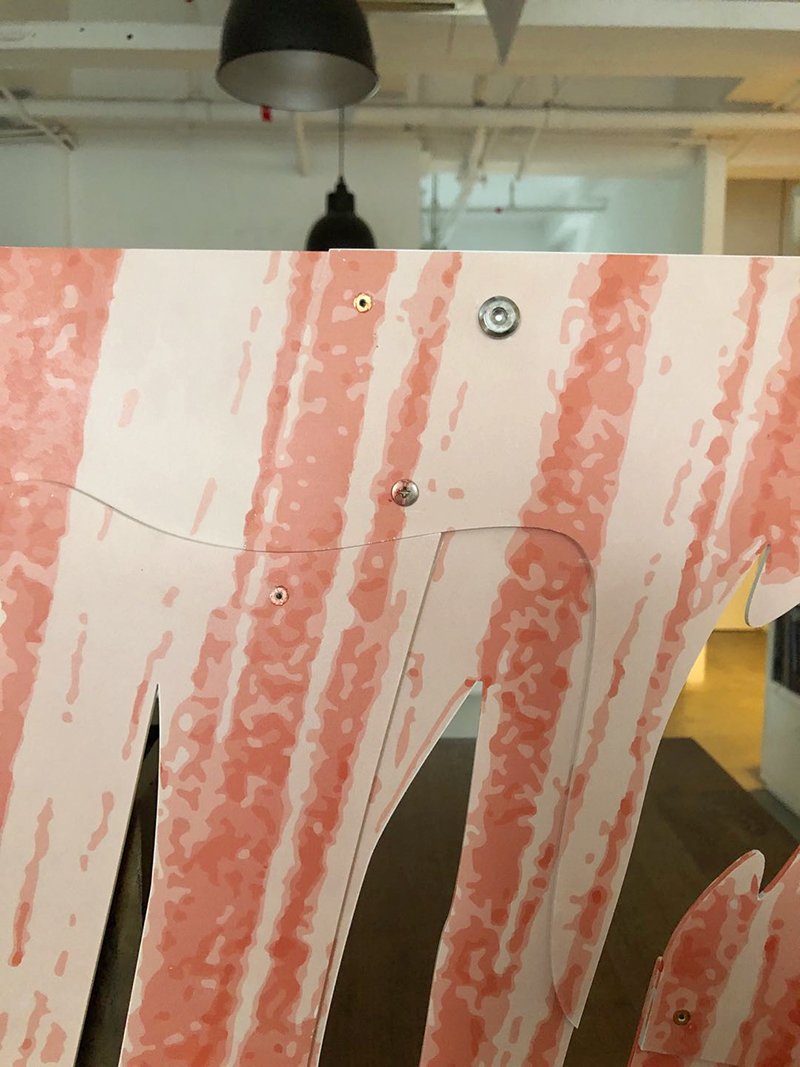

Meanwhile in Shanghai, UAP was laser cutting the aluminum components for each part and printing them with an exact, high resolution scan of my original ink brushstroke.

Some of the fine folks I never had the chance to meet, who made my sculpture. Thank you!

UAP hung all of the pieces at their correct angles (but not heights, for obvious reasons) for the client to see. You can really get a sense of how big BRUSHSTROKE is here.

Wrapped and ready to go to Zhongshan!

In all this time, the only physical thing I touched was one finish sample! I hope one day I can see BRUSHSTROKE in person...ONE DAY SOON. Thank you so much to all of the people who made this sculpture a reality: the Huafa Corporation, UAP Shanghai, and no doubt many others. I'm so grateful and amazed we could pull this off during a global pandemic without ever meeting in person.